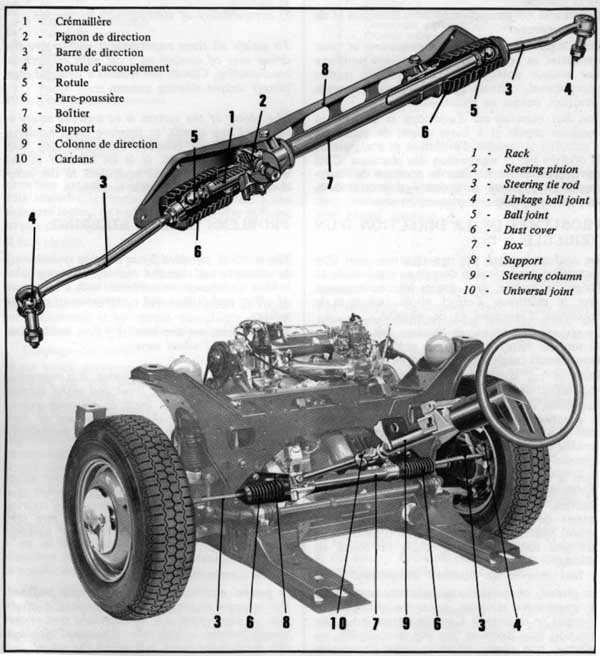

Rack and pinion steering

Steering column with flexible coupling

Reduction ratio 1/24.5

Turning radius beween kerbs:

10.9m = 17.9ft (Saloon)

11.8m = 19.4ft (Prestige)

11.8m = 19.4ft (Estate)

Turning radius between walls:

11.8m = 19.4ft (Saloon)

12.7m = 20.1ft (Prestige)

12.7m = 20.1ft (Estate)

Number of wheel truns from lock to lock: 4.5

Steering wheel diameter:

410mm = 16.14in

Optional: Rack and pinion power steering with powered return

Reduction ratio: 1/13.5

Number of wheel turns from lock to lock: 2.5

Steering wheel diameter: 380mm = 14.67in

This power steering operates on the same principle as on the SM, but has been

improved (servo control block in the passenger cabin and separate from the

steering system proper) and adapted to the vehicle (number of wheel turns from

lock to lock: 2.5 against 2 on the SM).

GENERALITIES

The steering on a car is the eqipment allowing the driver

to change direction at will as the road conditions dictate (how does one define self-evidence?).

The stability of the vehicle as well as the comfort and safety of the driver

depend on the steering system chosen. It is an essential element needing

careful design. To be perfect, a steering system must provide:

safety

ease of operation

precision

irreversibility

stability

compatibility of steering with suspension

apparently they forgot about reliability and

maintainability...

To satisfy all these requirements and to give the driver ease of control of a

car with exceptional roadhandling, Citroen has created a new and completely

unique steering system.

The object of the steering is to improve safety at high and low speeds, to

improve rapid handling, and to increase comfort by suppressing side-effects on

the wheel. It is an advance in the automobile field at least equivalent to the

introduction of hydropneumatic suspension.

PROBLEMS OF CAR STEERING

The comfort provided by a steering system may be characterised by the ease of

directing the vehicle under any circumstances, with a minimum of effort

and fatigue and a maximum of pleasure and safety.

What is tiring are

the turning forces needed and the amount of wheel turning.

In the case of mechanical steering, it is impossible to both reduce the

turning force and wheel turning distance. This usually leads to geared down

steering with the inconvenience of high wheel turning distance. This effect is

particularly noticeable with heavier vehicles.

With normal assisted steering, the turning effort when manoeuvering is

reduced by the addition of a hydraulic ram which allows a reduction of steering

gear ratio, but this system does not give firm steering at high speed with ease

of parking.

A new compromise is needed.

In a general assistance in manoeuvering

is prefered, but in order to avoid abrupt change of direction at high speed due

to over-light and under geared steering, a high ratio is retained although this

necessitates much turning of the wheel.

In other words, a normal assisted steering arrangement cannot satisfy the

three requirements: easy manoeuvering, sure and firm steering and low geared

steering.

The solution adopted by Citroen for the CX resolves this problem and fulfills

all driving demands at high and low speeds.

The functions of turning, force

on the steering wheel when manoeuvering and at speed and steering gear ratio

have been dealt with separately.

Turning of the wheels

This is effected

hydraulically and controlled mechanically , the driver merely activating the

servo control which determines the position of the wheels.

In any case, the

steering arm is actuated hydraulically which completely avoids any force due to

shocks on the wheels being transmitted to the steering wheel, whether such

shocks are caused by bad road surface (pot holes, ruts, etc...) or by

accidentally driving over an obstacle, or even by a puncture.

In actual fact (not visible in the pictures but in the Haynes

manual), a tiny shock absorbing piston is part of the steering cylinder.

In a word, the driver is always in complete control of the position of the

wheels of his car. Naturally in the case of hydraulic failure steering can be

mechanically controlled by the driver.

Force on the steering wheel

The force on the wheel

felt by the driver on turning or centring is produced by a cam linked to the

wheel. This force increases with the angle of the wheel and with speed.

When stationary and even for high turning angle the force onthe wheel

remains low, giving pleasant and easy driving even in town or twisty

roads.

The force on the wheel increases due to a hydraulic servo

controlled centrifugal governor. The curve of increasing force was defined so

that the driver always senses an effort small enough not to be annoying but

sufficiently high to remind him that the higher the speed, the less turning

angle is allowable to remain safe.

The centering force also increases in parallel and always returns the

wheels to the straight ahead position even if the car is stopped.

This is an important advantage which facilitates parking by allowing the

wheels to return to the straight ahead position, although the use of the anti

theft device allows the wheels to be locked turned on a slope.

On muddy ground, snow, sand or slippery surfaces the driver can get his front

wheels straight simply by letting the steering wheel retrun to centre.

As speed increases the cam recentres the wheels more firmly.

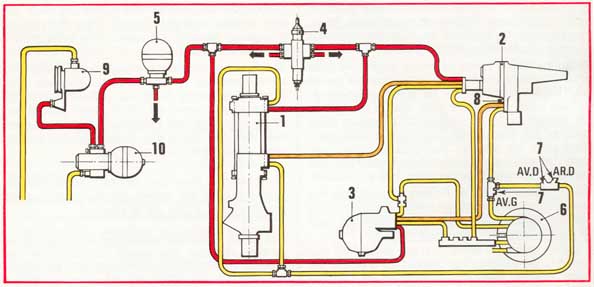

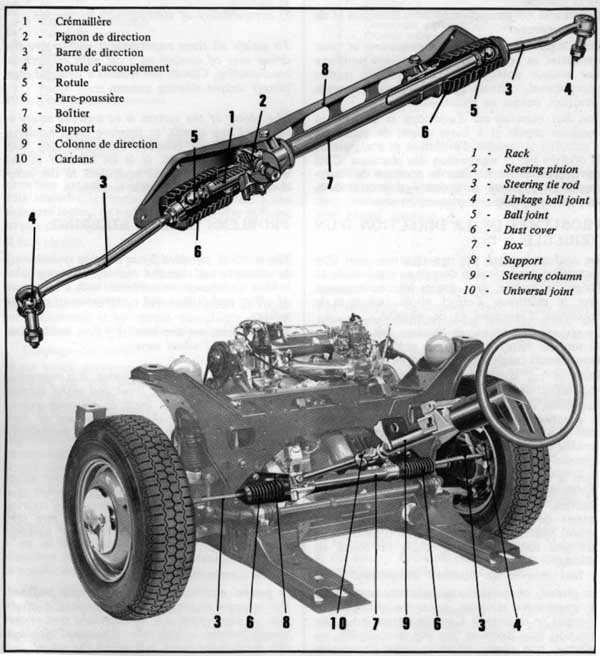

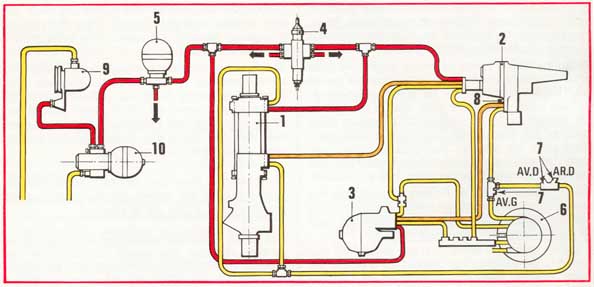

The picture shows the arrangement of the components of the

steering system.

To find out more technical details and

to understand the unit please click on it.

Details of

other units will be added later.

1 Steering Ram

2 Steering Control Unit (Servo Control)

3 Centrifugal Governor

4 Safety/Priority Valve

5 Brake Accumulator (through pipe)

6 LHM Reservoir

7 from suspension cylinders

8 Vent

9

High Pressure Hydraulic Pump

10 Pressure

Regulator

HIGH PRESSURE FROM PUMP

VARIABLE PRESSURE

RETURN TO RESERVOIR (Return to Reservoir)

Since the force on the steering wheel is independent of the force on the

wheel, the steering does not get harder with tyre wear, as with other systems.

Steering Gear Ratio

The ratio is chosen to give the best handling

possible. 2 1/2 turns of the steering wheel are needed from lock to lock (3

turns on the DS, 3 to 3,5 turns for normal assisted steering, 4.5 turns for

mechanical steering, 2 turns on the SM).

This reduced gearing is an

essential comfort factor since it limits the arm movement needed and allows the

hands to be placed correctly on the wheel for town or twisty road driving.

Allied to a small diameter steering wheel this gives incomparable handling

worthy of the high quality of the CX. (Sounds lovely,

doesn't it?)

The low gearing is also a safety factor since it gives the driver the

manoeuverability needed to avoid unexpected obstacles, which he could not do so

rapidly with higher gearing.

This rapidity is consistent with the "minimum reaction time" principle

Citroen introduced 20 years ago as a safety improvement when the zero movement

braking system was evolved on the DS.

Summing up, the CX hydraulic steering

system with servo-return gives the driver:

exceptional manoeuverability

more comfort and reduced fatigue

unique control of wheel position

realistic impression of increased car speed

These characteristics make this steering system original and may, therefore

require a short period of adaptation which, when acquired, will allow the driver

to benefit from all the advantages of the CX.

DESCRIPTION

(now, this part is heavily edited by me

and should leave no secrets)

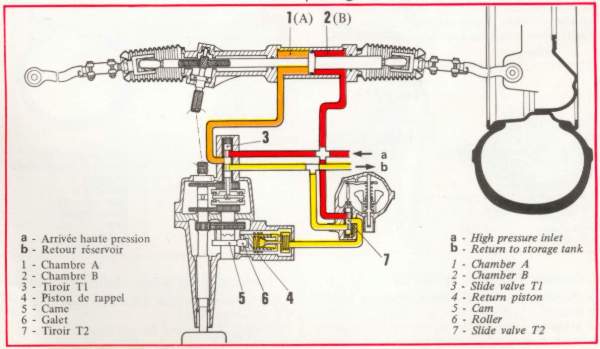

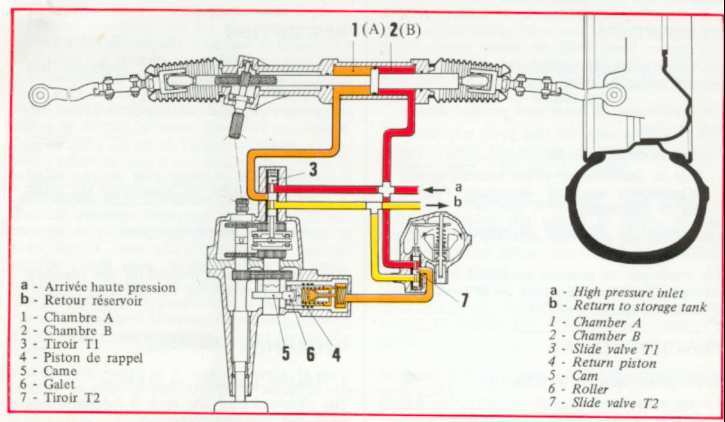

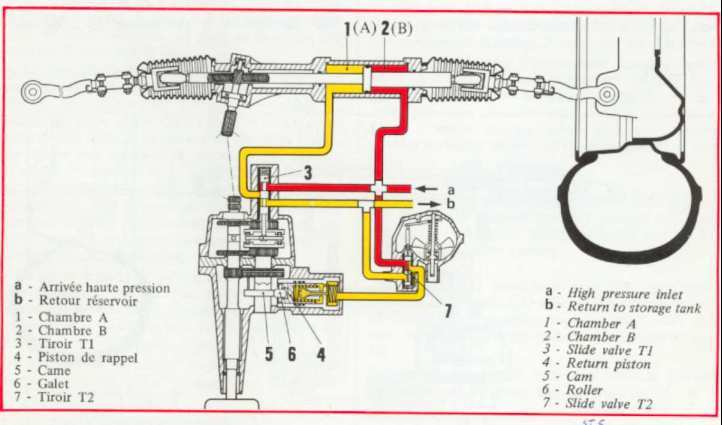

A differential piston type hydraulic ram actuates the steering gear.

A pressurised fluid distributor activates the ram.

A control box:

connects the steering gear to the wheel with an angular lag controlling the

distributor

controls the centering system

A pressure regulator (centrifugal governor) modulates the centering

force as a function of speed.

To make this more understandable to the non-automotive engineer, let us have

a closer look at the picture below:

Click on the picture for more detail.

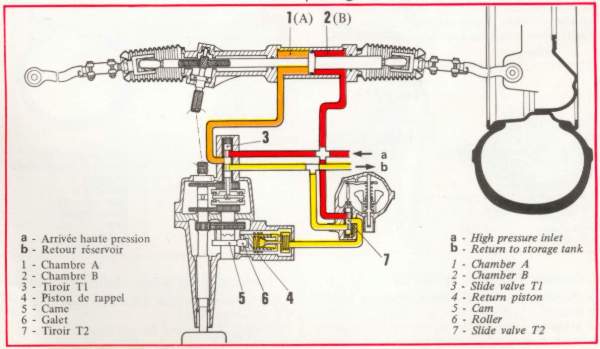

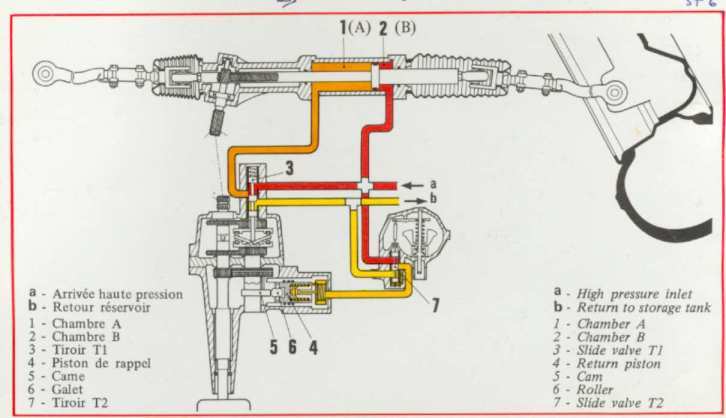

The differential piston is the one in the steering ram. Differential because

of the different surface area of the piston on both sides. When you look closer

at the picture you will notice that the diameter of the rod is different on both

sides of the piston which influences the piston's surface area. In fact it seems

to be calculated in such a way that the surface area of the left side is twice

that of the right one.

Remembering Physics - force F equals pressure P multiplied by the surface

area A:

Chamber one: F1=P1 * A1

Chamber two: F2=P2 * A2

When no whee no wheel movement is required, the forces F1 and F2 must be

equal.

F1=F2

Now we know that by design, the surface area of the left piston is about two

twice the surface of the right one .

In order to maintain the balance of the two forces the equations must look

like:

F1=1/2 * P1 * A1 and

F2=P2 * 1/2 * A2

so

F1=F2 =1/2*P1*A1=P2*1/2*A2

That means that the pressure in chamber 1 must be half of the pressure in

chamber 2 to maintain an equilibrium of the steering forces F1 and F2. This also

explains the mysterious "hp/2" found in the Haynes Manual.

For this equilibrim to be held, the pressure in chamber one must be isolated

from the rest of the system, otherwise the car would start steering to the

right. This is done by a slide valve 3 in the "steering control unit".

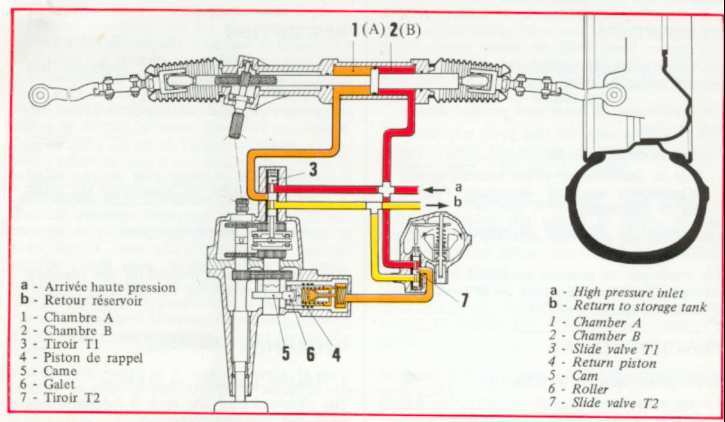

Steering action

Steering to the right:

For any movement of

the steering ram, the equilibrium of forces F1 and F2 must be upset. This is

done by sliding the valve 3 out which causes lower pressure fluid in the left

cylinder to be pressed into the return pipes (yellow) by the forces of the high

pressure fluid in the right half of the ram. (You may hear the famous slurping

sound) The ram will move to the left and the car will steer right. Returning the

valve will then restore equal forces F1 and F2.

Steering to the left:

For this, F1>F2, the ram moves right and

the car left. The slide valve must now move down and fluid under high pressure

passes into chamber 1 and gradually builds up pressure. Equal pressure in both

cylinders however means different forces because of the different surface areas

of the piston, so the ram will move right, turning the wheels left.

The slide valve moves by an ingenious mechanism which must be achieved by

having a different gear ratio of the front and rear sprockets of the second

shaft 5 in the steering unit. This causes a precise movement of the slidevalve 3

proportional to the turning of the steering wheel.

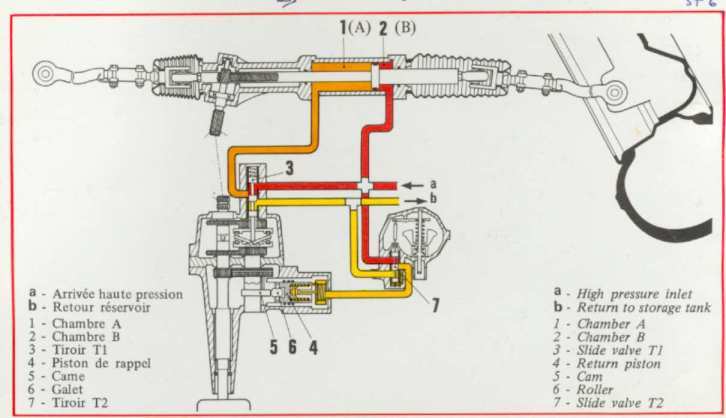

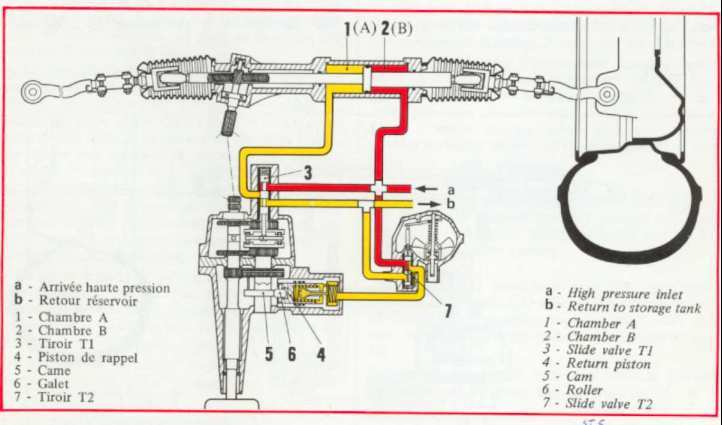

Self Centering

The Self Centering technique in fact is much simpler than

I first expected. Because I have problems with my steering unit, I thought much

about how it is mean to work. A hint was given in the Haynes manual, which is a

copy of the material published here (originally by Citroen).

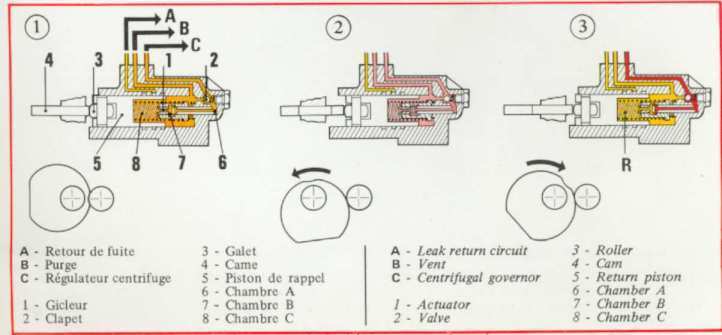

The basic

principle is very simple and the magic word is "eccentric cam".

This

eccentric cam is located at 5 in the previous picure and rotates proportionally

to the turning of the steering wheel. A roller in between, displaces a piston

for the self centering mecahnism.

The system is best understood if one just

forgets about the hydraulic pipes, pressures and the governor in the first

place. Pure mechanics does the job.

The following picture will illustrate

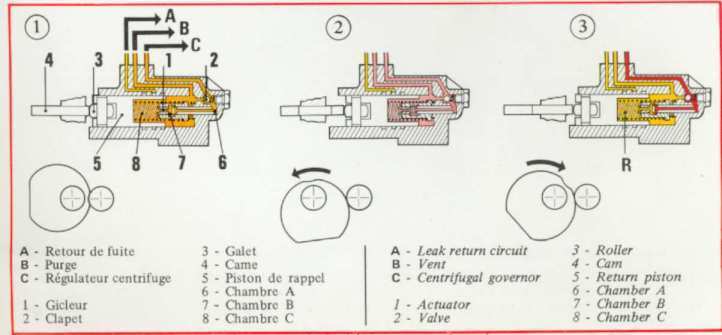

the function.

The piston is spring loaded and excerts a force over the roller to the

eccentric cam. This force will cause the steering wheel to return to its centre

position where a little notch will keep it there.

To increase the self centering force, the force on the cam needs to be

increased. Because there is only one spring to give a basic self centering,

additional force must be provided by using hydraulic fluid pressing at the

piston and thus adding to the force on the cam.

This force should be

dependent on the vehicular speed to give safe handling. This is achieved by the

Centrifugal Governor, which is a similar valve as found in the Steering Control

Unit. A high pressure pipe goes into the unit, modulated pressure comes out and

of course a return pipe. Depending on the road speed (driven from a special

"speedo" cable), little wings in the unit rotate with a speed proprtional of

that of the vehicle. When speed increases, the wings are forced to fold down

with the aid of increased "centrifugal" force, pushing the valve mechanism down

and allowing fluid with higher pressure to act on the self centering piston.

(See details in the following pictures.)

The Flywheel weights fold down.

The governor valve opens and increases pressure on centering

cylinder.

The feel of the steering in your CX is thus almost absolutely artificial!

Intro

Story, Driving

Experience

Mechanics

Electrical

DIY

Buyers' Guide

Pix

FAQ (Good CX FAQ! Also with lot's of

DIY info)

Linx

Home

Contact me